Our 150 seamstresses are true masters of their craft.

The philosophy of our production: the key to longevity is quality.

ÉMANOU blouses are sewn by women, for women. Our sewing manufactory consecutively supports women in becoming qualified seamstresses who handle the complex and progressive techniques that underpin our designs.

Behind every success story, there is a dedicated team. Our vision is not only to produce the best shirts, but also to respect and uphold the rights of our employees throughout the value chain.

Safe and healthy workplaces that protect physical and mental well-being are a matter of course for us.

We want each of our female employees to have equal opportunities, fully aware of the value of their own knowledge.

We also strive to foster healthy relationships of appreciation and trust among employees.

SUSTAINABILITY AT EMANOU

At ÉMANOU, we made a sustainable and transparent approach a core value that underpins the work towards becoming a wholesome brand. Our manufacturing process begins and ends in Europe, which puts us in full control of producing ethically and with full awareness of our supply-chains. This sense of conducting our business lies at the very heart of our story and we are proud to have the opportunity to communicate that.

What is our supply-chain?

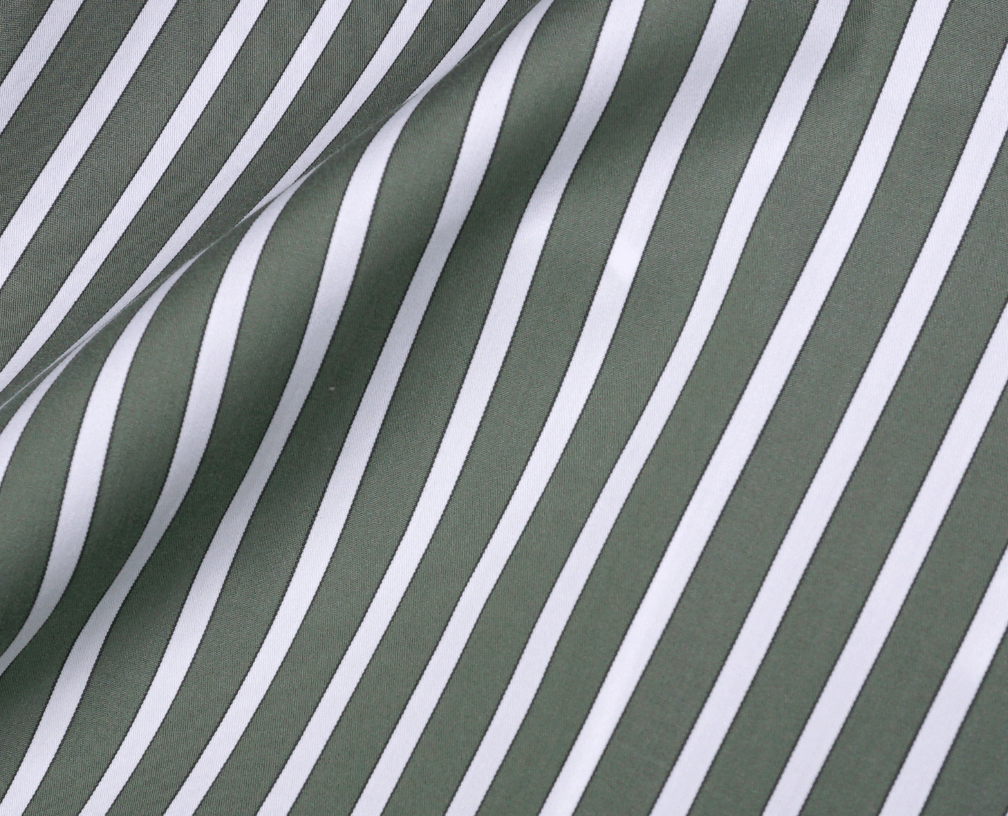

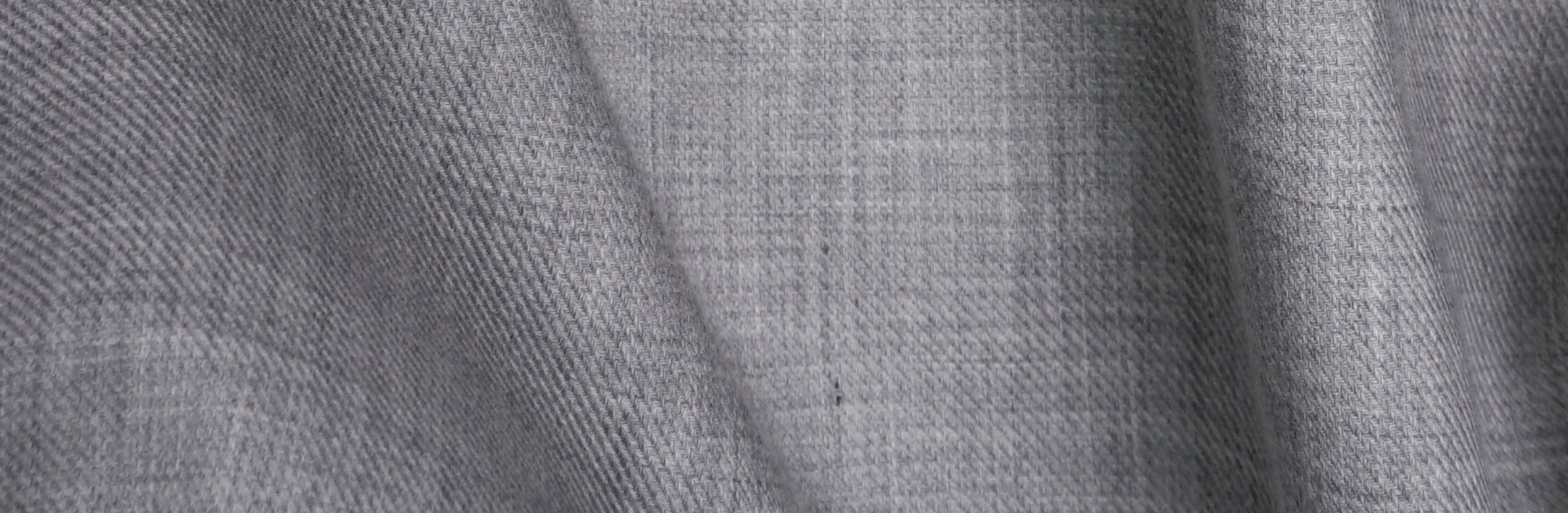

Our supply chain starts with the fabric manufactories in Italy. We partner with 4 different mills, all of which we have worked with for many years.

From the mills, we receive large fabric rolls at our sewing facility in the northern part of Poland. This is the heart of our operations, where our blouses are created- from their construction to the final, folded product. Any hardware, such as mother-of-pearl buttons which we may use in our products, is ethically sourced from partners that we have established solid relationships with.

While producing fashion may never be fully sustainable, we aim to be as transparent as we can afford to and use the best materials at hand, in order to minimise waste. For coming seasons, we are working towards substantially reducing plastic usage and constantly looking for new processes to optimise. Should you have any questions or concerns related to our sustainability policy, please do not hesitate to contact us: sustainability@emanou.com.